How Many Tools Are Used in Lathe Machine?

Lathe machines are vital in the world of machining, playing a key role in shaping, cutting, and finishing materials with precision. Understanding the various tools used in a lathe machine is crucial for both beginners and seasoned machinists. This blog explores the different types of lathe tools, their functions, and their importance in the machining process.

Understanding Lathe Machines

Before diving into the tools, it's essential to understand what a lathe machine is and its basic operations. A lathe machine is a tool that rotates a workpiece on its axis to perform various operations such as cutting, sanding, knurling, drilling, and deformation. The primary purpose is to shape the workpiece into the desired form with precision.

Types of Lathe Tools

Lathe tools are categorized based on their functionality and the type of operations they perform. Here are the main types of lathe tools:

1. Cutting Tools

Cutting tools are the most common tools used in a lathe machine. They are designed to remove material from the workpiece to create the desired shape. Cutting tools come in various shapes and sizes, each serving a specific purpose.

Turning Tools: Used to remove material from the outside diameter of a workpiece, turning tools shape the external surface.

Boring Tools: These tools are used to enlarge a hole or cylindrical cavity in a workpiece.

Parting Tools: Also known as cutoff tools, they are used to cut a piece off from the main workpiece.

Thread Cutting Tools: Specifically designed to cut threads into the workpiece, these tools are essential for creating threaded parts.

2. Drilling Tools

Drilling tools are used to create holes in the workpiece. While drilling can be done on a lathe, it is often more efficient to use a dedicated drill press. However, lathe drilling is still common for precision work.

Center Drills: These are short, stubby drills used to create a starting point for a larger drill.

Twist Drills: Commonly used for drilling holes, twist drills come in various sizes and are versatile.

3. Forming Tools

Forming tools are used to shape the workpiece without removing material. These tools are typically used for creating specific shapes or profiles on the workpiece.

Knurling Tools: Used to create a textured pattern on the surface of the workpiece, often for grip.

Chamfering Tools: These tools are used to create a beveled edge on the workpiece.

Tool Materials

The effectiveness of lathe tools also depends on the materials they are made from. Here are some common materials used for lathe tools:

High-Speed Steel (HSS): Known for its durability and ability to withstand high temperatures, HSS is a popular choice for many lathe tools.

Carbide: Carbide tools are extremely hard and can maintain a sharp cutting edge longer than HSS tools. They are ideal for high-speed machining and cutting hard materials.

Ceramic: Ceramic tools are used for high-speed machining and offer excellent wear resistance. They are particularly useful for cutting hard materials but can be brittle.

Diamond: Diamond tools provide the highest hardness and wear resistance, making them perfect for precision machining of very hard materials.

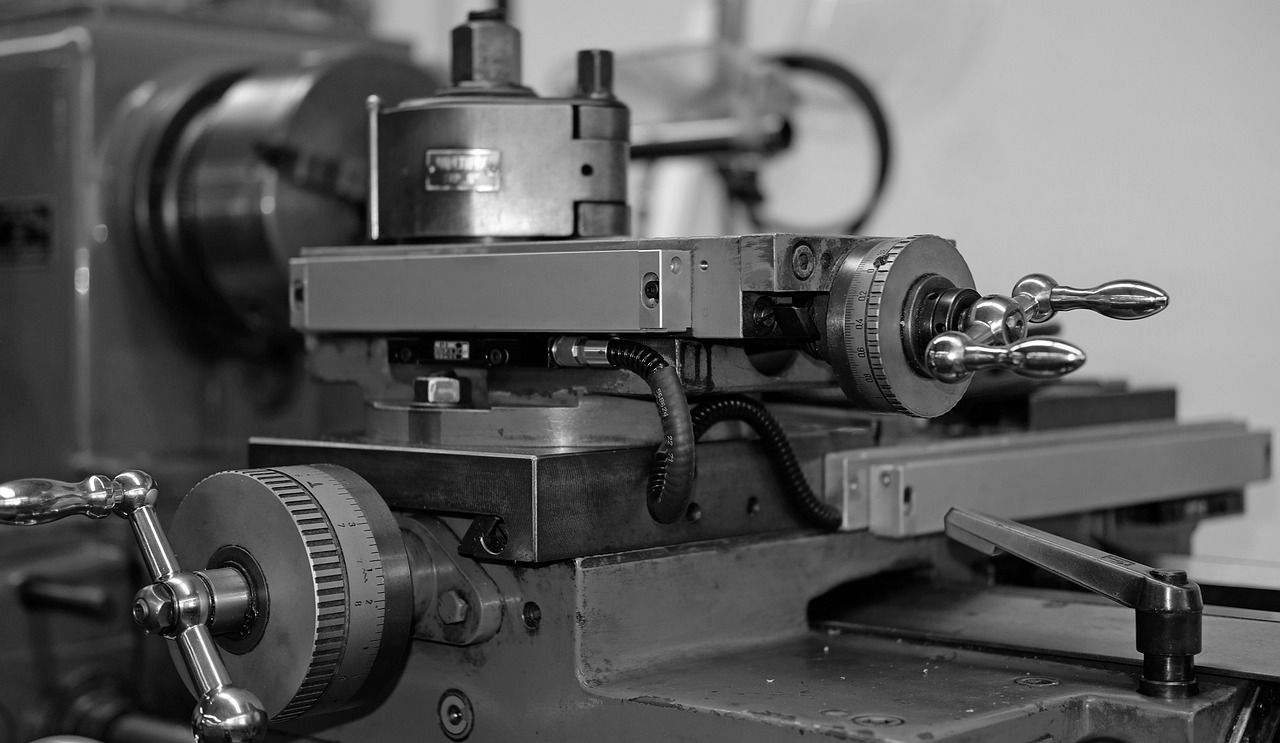

Tool Holders

Tool holders are essential for securing the cutting tools in the lathe machine. They ensure the tools are held firmly in place, allowing for precise and stable machining operations. Common types of tool holders include:

Quick Change Tool Post: Allows for rapid tool changes, increasing efficiency and productivity.

Standard Tool Post: A versatile option that can hold various tool types securely.

Boring Bar Holders: Specifically designed to hold boring bars for internal cutting operations.

How to Choose the Right Tools

Selecting the appropriate tools for a lathe machine depends on several factors:

Material of the Workpiece: Different materials require specific tool materials and designs.

Type of Operation: The intended operation (e.g., turning, drilling, threading) dictates the tool choice.

Precision Requirements: Higher precision requirements may necessitate the use of specific tools or tool materials.

Tips for Effective Tool Use

To maximize the efficiency and longevity of lathe tools, consider the following tips:

Proper Tool Maintenance: Regularly inspect and maintain tools to ensure they are sharp and in good condition.

Correct Speed and Feed Rates: Adjust the lathe's speed and feed rates based on the tool and material to prevent tool wear and achieve a smooth finish.

Use of Lubricants: Lubricants can reduce friction and heat, extending the life of the tools.

Conclusion

Lathe machines are indispensable in machining, and understanding the tools used in these machines is crucial for achieving precision and efficiency. From cutting and drilling to forming tools, each plays a specific role in the machining process. By choosing the right tools and maintaining them properly, machinists can ensure high-quality work and prolong the life of their equipment.